The Only Guide for Recycling Lives Services

The Only Guide for Recycling Lives Services

Blog Article

Indicators on Recycling Lives Services You Need To Know

Table of Contents10 Easy Facts About Recycling Lives Services ExplainedThe Buzz on Recycling Lives ServicesThe Only Guide to Recycling Lives ServicesThe 6-Minute Rule for Recycling Lives ServicesA Biased View of Recycling Lives ServicesNot known Details About Recycling Lives Services

E-waste recycling is a lot more complicated than standard waste recycling. When e-waste is collected and carried to the reusing centers, workers sort the e-waste right into classifications according to their kinds and designs.

Here, e-waste is tossed into a huge equipment and is shredded into little items, yet prior to that, it should initially go via a process called de-manufacturing, which describes the activity of disassembling a product into components. https://www.goodreads.com/user/show/182346883-zona-beardsley. This procedure is to eliminate all the possibly dangerous products in electronic gadgets that will certainly damage the maker or infect the atmosphere as soon as got rid of into land fills

Excitement About Recycling Lives Services

Next off, the waste is further separated with water. At this stage, practically everything leftover are non-magnetic products; they will go with one more machine loaded with water, where products with a reduced family member thickness, mostly plastic, will move, while other materials, like glass, will sink. Finally, before recycled materials are offered, is to examine if there are any type of staying beneficial products stayed with the plastic.

Recycling Lives Services - The Facts

Recycling e-waste not just avoids poisonous substances from entering our bodies and into the setting, but the process additionally lowers the damaging ecological impacts developed by the extraction and mining of virgin materials. Besides, the potential financial advantages that can be originated from this industry are huge. The disposed of e-waste in 2019 alone deserved greater than US$ 57 billion.

Computer systems and electronic equipment are made from multiple sorts of plastic, steel, glass and rare-earth elements. Our objective when recycling electronic devices is to divide the various materials from each other. The "product" we create from reusing is clean apart streams of recycled plastic, iron, steel, copper, light weight aluminum, glass and rare-earth elements.

2-1/2 min video clip reveals electronic devices being reused at a SLS center. The client reports we are able to generate depends on how devices is taken care of prior to being recycled.

5 Easy Facts About Recycling Lives Services Shown

Our significant recycling sites are geared up with automated industrial shredders, conveyor systems and sorting devices. This first action prepares the e-waste to begin the process of dividing plastic components from steel, copper, light weight aluminum, glass and other assets.

After shredding, the conveyor belts press the e-waste with magnets, eddy currents, infrared cameras and air jets. These modern technologies iron out different material kinds and separate arranged material from the e-waste hop over to these guys stream. Iron and steel is divided from the e-waste, then aluminum, copper and motherboard are divided. After the bulk metal is removed, the e-waste stream, which is now primarily plastic, is more divided into abdominal muscle from polystyrene plastic.

Facts About Recycling Lives Services Revealed

Dividing Iron and Steel from e-Waste After shredding, conveyor belts transfer the shredded computer systems and e-waste under a powerful magnet, which divides iron and steel from the shredded e-waste (recycling lives services skips hire). The steel and iron are gathered in pallet sized bags and gotten ready for sale as recycled commodity products. Dividing Aluminum, Copper and Motherboard from e-Waste After passing under the magnet, the e-waste remains to move using the conveyor belts with added mechanical separators

An aesthetic evaluation and hand sorting boosts the quality of the extracted products. The separated streams of aluminum, copper, and motherboard are collected in pallet sized bags and prepared for sale as reused product materials. Benefits of Recycling Recycling vs - https://www.evernote.com/shard/s581/client/snv?isnewsnv=true¬eGuid=bb30160d-1cb5-4be3-ff44-774e16e166ad¬eKey=AR0fPTLaigniRPlb53THnuV_07aWj4UsY2O27pAwguc_8MxcLKZV002nQw&sn=https%3A%2F%2Fwww.evernote.com%2Fshard%2Fs581%2Fsh%2Fbb30160d-1cb5-4be3-ff44-774e16e166ad%2FAR0fPTLaigniRPlb53THnuV_07aWj4UsY2O27pAwguc_8MxcLKZV002nQw&title=Recycling%2BLives%2BServices%253A%2BYour%2BPartner%2Bin%2BSustainable%2BWaste%2BManagement. Virgin Material The separated products are used to make future generation products

Utilizing recycled material in the manufacturing of brand-new items has benefits that go much beyond product reuse. It reduces air pollution and carbon exhausts, reduces power and water intake and keeps useful products out of landfills. As each commodity is divided from the e-waste stream, the material is accumulated in pallet sacks or huge cardboard boxes and shipped to another cpu or directly to a maker.

Recycling Lives Services for Beginners

It minimizes contamination and carbon emissions, lowers power and water intake and keeps beneficial materials out of landfills. SLS has earned a track record of producing excellent quality recyclables out of our centers. Producers and secondary cpus seek us out in utilizing our recycled assets. SLS is at the leading edge of developing ingenious e-waste recycling options.

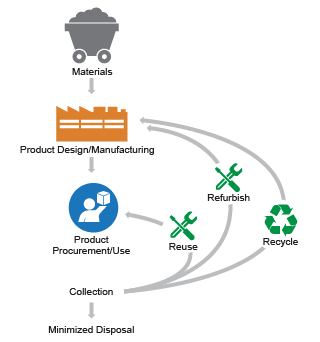

Customers can get fewer things while reusing and reusing more. Firms can develop products created to last, not to be changed, and to be reused.

Report this page